The Ongoing Solar Install Journal

This post is an update on how the system has been performing.

The Addition of Sense

Part of the way into March, I was talking with my solar company salesman and he mentioned whole-house power monitoring that included solar production - namely, Sense. Since I'd been looking for a solution (and my desire to build one did not match up with my available time), I went for it. About $400 later, we had whole-house power monitoring...again. We used to, with the TED-5000, but it had died a few years ago after a very long and good run of monitoring.

Intense Tracking

Overall, I like it very much. I prefer to warehouse my own data, which is the only detracting attribute of Sense: it requires a constant uplink and stores nothing locally. Everything you do with your Sense, you tend to have to do via the webapp or the phone app. The phone app is, however, very useful.

Aside from totals, it uses machine learning to identify device patterns and can detect when individual devices turn on and off. With that info, it can tell you how much power a particular device uses over time. It takes time to get a decent bunch of them found, but all in all it's pretty neat and quite functional. But since this isn't a sales pitch for Sense (and they sure aren't paying me to talk about it), let's just focus on the graph above. That's May's recorded usage, and for the most part (i.e. minus a couple hours one day when my firewall lost power before I woke up), it is a complete summary of our use (blue bars, green plug icon) and our daily generation (orange bars, sun icon).

You can probably ignore the dollar figures - I do... it's based on a flat rate, so I punched in $0.12, which is in the neighborhood but doesn't account for the usage tiers my provider has.

May was, as you can probably tell, a good month.

Generated Credits

We have, so far, not had to pay for a single kWh since the February billing cycle. We're already up to nearly a month's worth of kWh credits, or around 2,200.

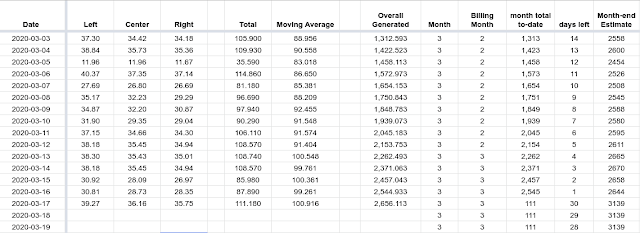

I have been able to fill in a couple of months-worth of bills now, and here are the results:

Thanks to the detail that Sense captures, I can calculate what we would've paid if we hadn't had solar. Basically, for May we saved around $80. Once the system is paid off, that will look more like a $350 savings.

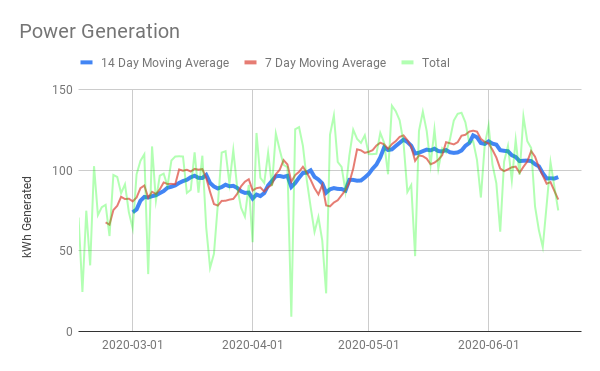

System Performance

So far the system is performing beyond expectations. Lately the generation has been a little more spotty due to daily cloud-cover and thunderstorms, but even with those our worst day in the last seven was 52 kWh, our best 105 kWh, and the 7 and 14 day moving averages (as of today) were 81.8 and 95.7 (respectively). The 14 day moving average for last week was around 105 kWh, and at the end of May it was 116 kWh.

I have a chart that tracks all of these figures, which of course I hand-enter daily from my inverters:

It's important to note that as long as we're generating more than we're using overall, we're in good shape. A few bad days here and there does not break the bank, and right now we're continuing to increase our credits.

Our expected and actual power generation is tracked on the Sunny Portal (SMA's PV management site):

Note that for June, the month that we're in, obviously we're still in it and so the total yield bar is justifiably below the expectation. Also note that January we were technically not online, and February we were turned on part-way through the month.

Comments, Considerations

The guy who came out to rebury our CATV cable had also used my solar provider, even the same salesman. We had a good laugh and compared notes. He managed to get his system installed during the 30% tax rebate days.

Overall, I am extremely happy and pleased with the system. It is operating beyond my expectations and is now at the point of operating basically autonomously. I only baby-sit it still because I'm neurotic like that.

Batteries

Would I invest in batteries? At this time, no. My situation unfortunately (or fortunately, given the cost of batteries) does not lend itself to such an investment. For what it's worth, the power company is my "battery" and since I'm feeding in more to the grid than I'm using per day (most days), I really have no qualms about not running my own battery bank at the moment.

I would consider investing in them if the prices dropped dramatically, or an alternative energy storage solution (alternative to typical batteries) became readily available. I've read about one that uses pumps and a special liquid, but the tech isn't really ready for production yet. That said, the only time batteries would benefit me here is during a major outage. So, let's hope we don't have one of those...

The Panels

Do I like my entire roof covered in panels? Why yes, yes I do. To be perfectly honest, I've never been a stickler for aesthetics, though I have developed a more critical eye in my older years. That said, I want power...lots of power, and so I put as many panels up there as I legally could. Given how much power we are able to produce, and the fact that we've zeroed our bill the last few months, I have no regrets. And as long as we continue to zero our bill through to the end of the year, I will continue to have no regrets.

The Electric Car

I've had a few people now ask about our solar. They also get excited when they see my little Focus Electric charging in the driveway. "Oh man, and you charge this with your solar, don't you?" they ask. No...not really. Sorry.

The car doesn't care where it gets its power from, and my charger unit (an OpenEVSE box), runs off the mains. The grid-tie doesn't give me the option to run separately, though I think SMA might offer some solutions to that effect. That said, given the credit system with my energy provider, why bother? Currently I don't drive it much, so it doesn't draw any more than what is necessary to keep the battery topped and cooled during hot days. When I was driving it daily, I'd chew through the 22 kWh battery almost completely. That said, it was probably more like 18 kWh, since you can't run it to zero.

18 kWh per day off our current generation totals would probably hurt a bit, but it looks like what we're generating would more than cover it. Even if it didn't, even if we were breaking even with our usage and generation, and the car us over by 360 kWh onto the bill, that'd be only like $50 a month. Still way cheaper than gas for doing 50 miles a day for 20 work days.

Other Solar Tech

One of the other companies I was looking into called me and wanted to know if they could close my file. I'd already let the guy down once, but I guess he was a glutton for punishment. And once again I filled him in on what I bought. He let out a most annoying groan when I told him I'd gone with string inverters (his company does optimizers).

Now, here's the thing. I've read the sales and specs sheets myself, I've studied the tech, and I've read what is apparently the only available research out there that bothered to compare these types of systems. Obviously, the industry in general - and the solar research institutes in particular - need to do better here. But given what I learned, and my specific situation of full sun all day long (barring clouds), I had and still have no reason to believe that optimizers or microinverters would win me much benefit.

For kicks I tried to figure out a way to perform a comparative calculation between the two proposed systems (the one I chose, and the one I didn't). I decided that the two most sensible numbers to use were the system design watts, and the total expected production in kW.

Dividing total expected production by system design, we end up with two almost-dimensionless figures: 1.388 and 1.407 expected kW per design watt, chosen and not-chosen systems respectively. What this basically says is that these two systems are nearly identical. Over the course of a year, I should get almost the same kW per unit design watt. In other words, the optimizers would have to do something very special to provide me additional benefit.

My system is the lower of the two numbers (1.388), and yet because we could afford more panels, we wound up with a better overall value. We should generate around 4000 kW additional power over the course of the year, or about 1.6 months-worth.

Now, the problem with the above calculation is that I really don't know how well one can expected optimizers to...well...optimize panel output. So many of the major worries that are thrown at prospective customers - such as "a single bad panel will take out a whole string" - are passe. The better panels have bypass diodes, so that isn't a problem. A weaker panel might slow things down a little, but the underlying question is: how much loss do you have to incur to make the optimizers worth it?

I won't go into a bunch of "what if's" here, if only to keep this readable and on-topic. What I can say is that this is where we need more research, and unfortunately the only research I was able to find, when I made my decision, basically strongly supported the string inverter technology. SMA also recently started advertising shade-fix boxes for individual panels, which are meant to act almost like optimizers but can be used on a panel-by-panel basis (instead of having to attach them to every panel in your array). Do they work? Are they worth the money? I really can't say.

What I can say is that given the overall costs of the two candidate systems, and the expected outputs and performance to-date, I have no regrets with choosing the technology that we did.

Moving Forward

I'll update this blog again once a few more months have passed. At this point, anyone following this should expect business to proceed as usual: the panels will keep generating power, my bill will remain practically zero, my electric car will be sitting in the driveway doing nothing much of anything.

Daydreaming

If I were to be in a position to build my own community, I would definitely do this:

- Put solar on every house and centralize the upkeep of them all - basically give the people living there nothing much to do other than enjoy the benefits.

- Work with the local energy provider to set up a local-to-the-community battery substation, sort of like what was done in Australia (though theirs was, like, state-sized).

The key benefits I'd be looking to extract from the above would be:

- With solar on every roof, the community generation should be utterly fantastic - far more than what the community as a whole would or could use.

- With a battery substation, we'd be in a position to offer community-wide power during outages, for as long as the batteries could hold out.

- The battery substation could also be useful during brownouts or whenever the main energy provider needs a bit of a break on the grid, or to supplement the provider during the evenings/nights.

Of course, to achieve the above, you'd need the community to pay into it, either via HOA fees (egad, I hate HOAs), or as a community "power bill." Without running the numbers on upkeep costs (mainly for the batteries), I couldn't say what that number would be. But as soon as the solar was paid off, the batteries and other infrastructure would be all you'd be on the hook for - aside from the occasional re-roof job or when panels start to wear out.